INTRODUCTION

Only Yamaha can offer your production lines Total Optimization.

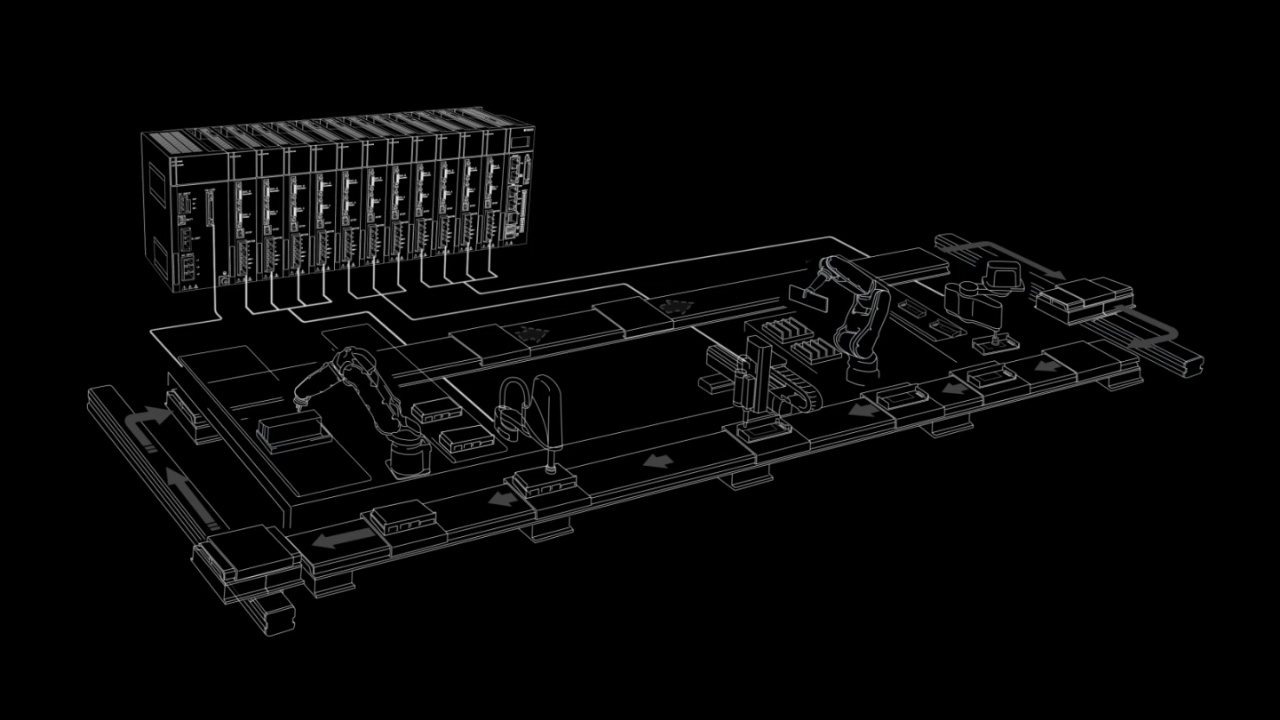

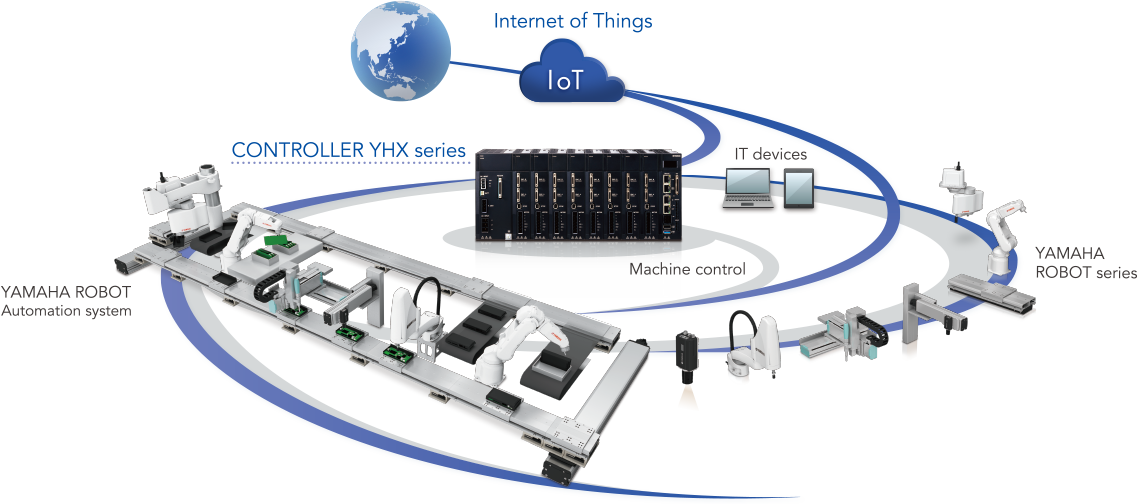

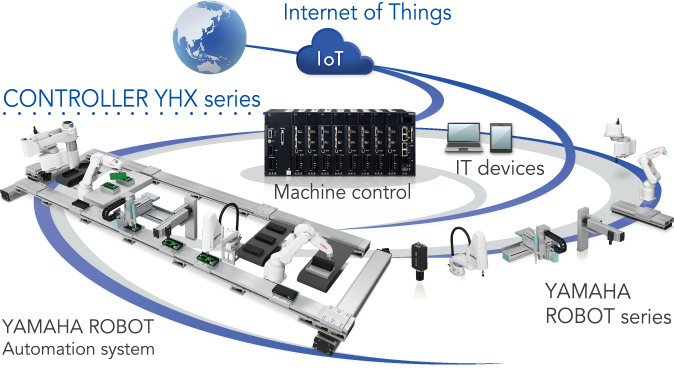

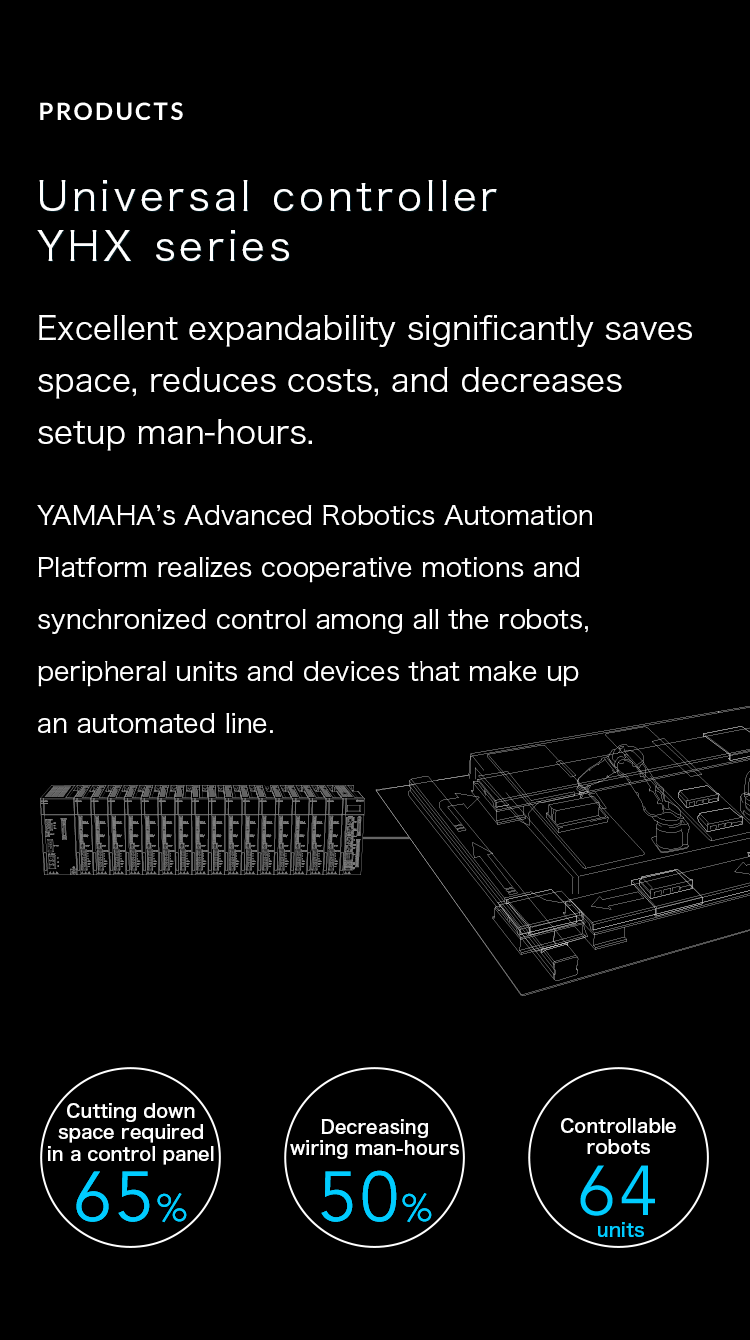

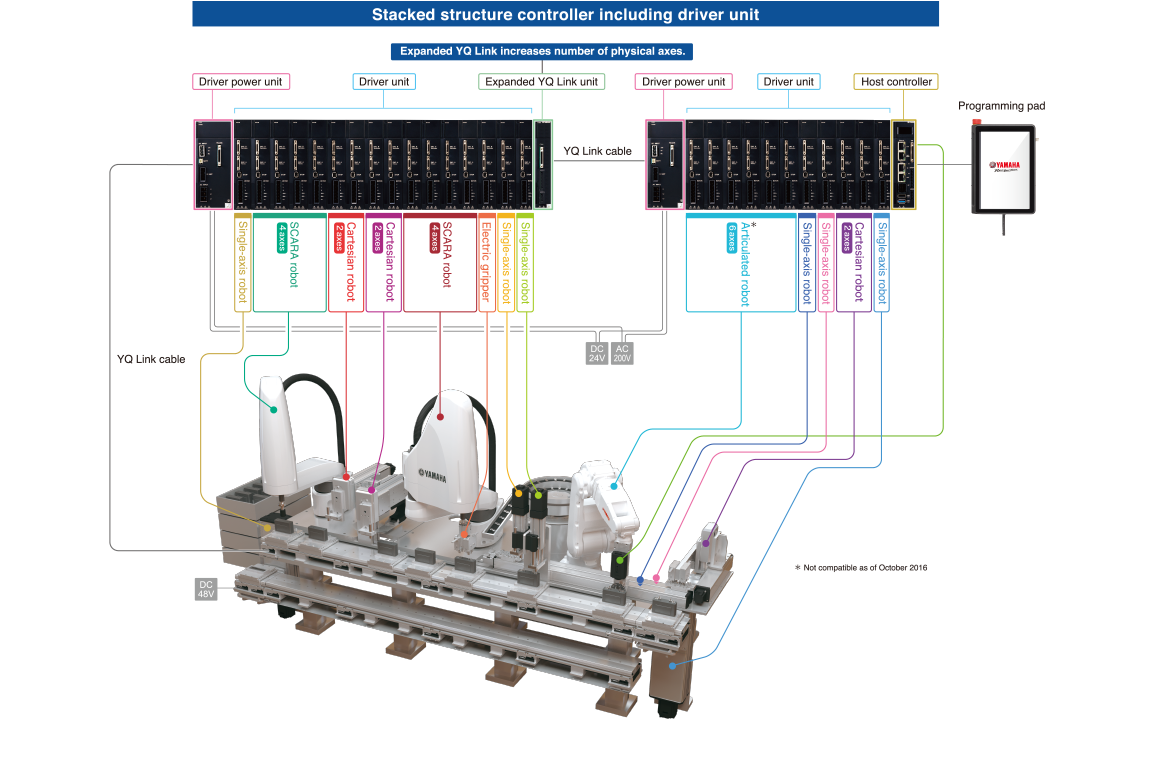

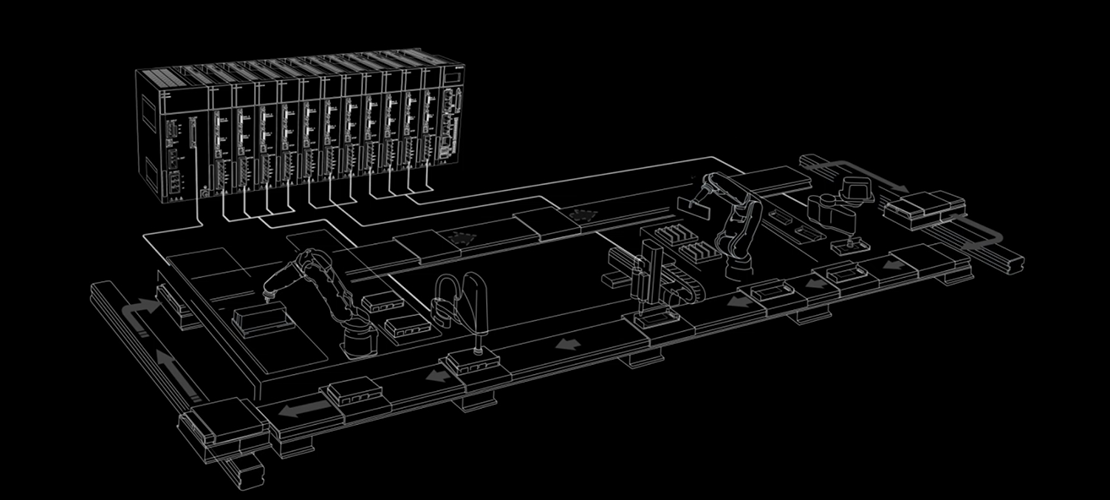

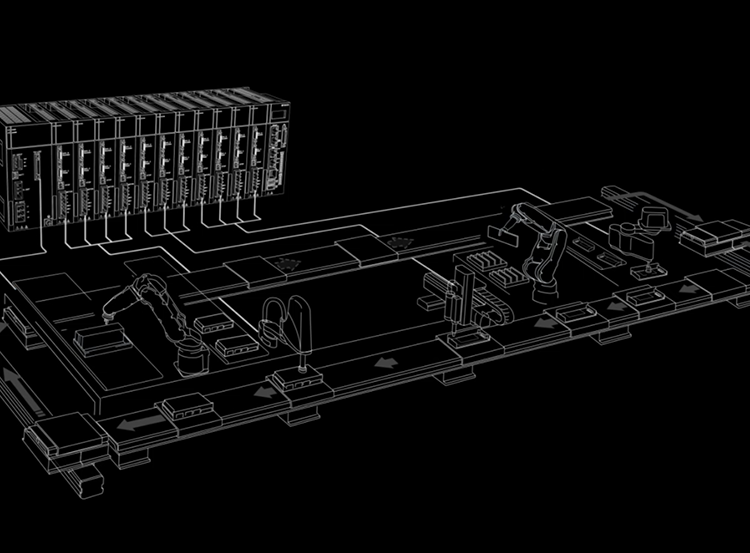

Yamaha Motor Co., Ltd.’s new “Advanced Robotics Automation Platform” realizes the effective,

quick, low cost construction of automated manufacturing lines, with a significantly greater unity with IoT.

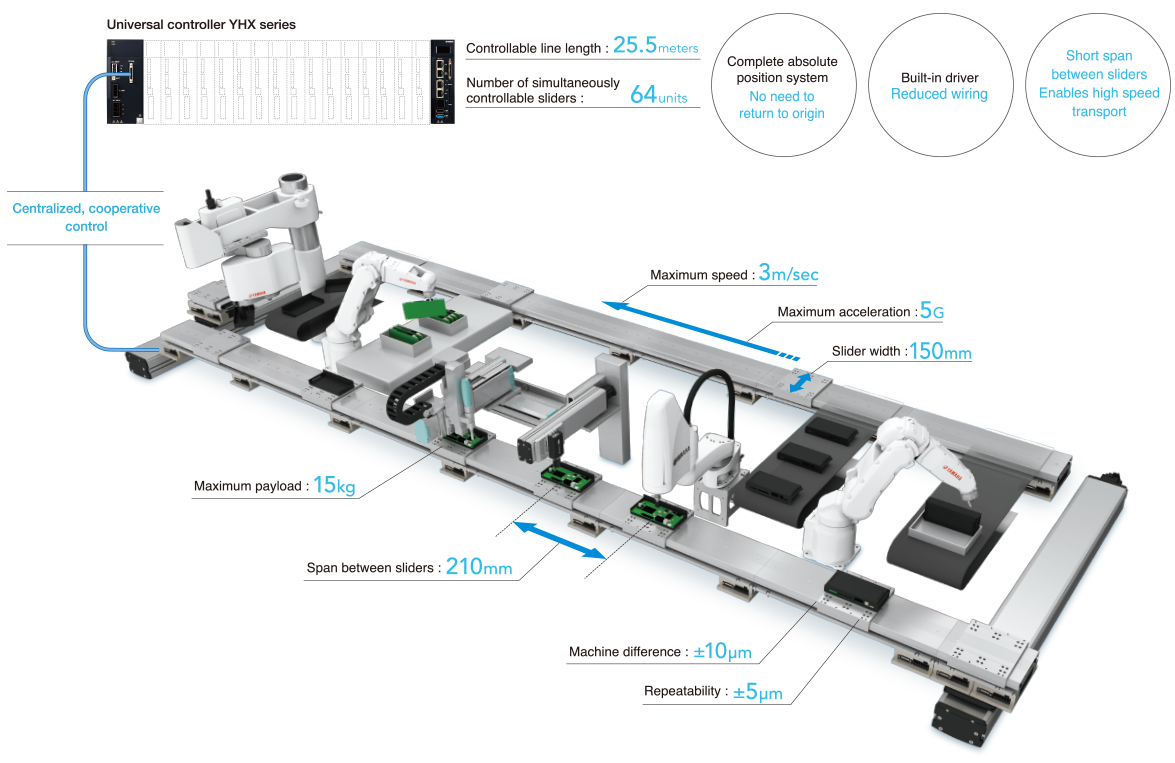

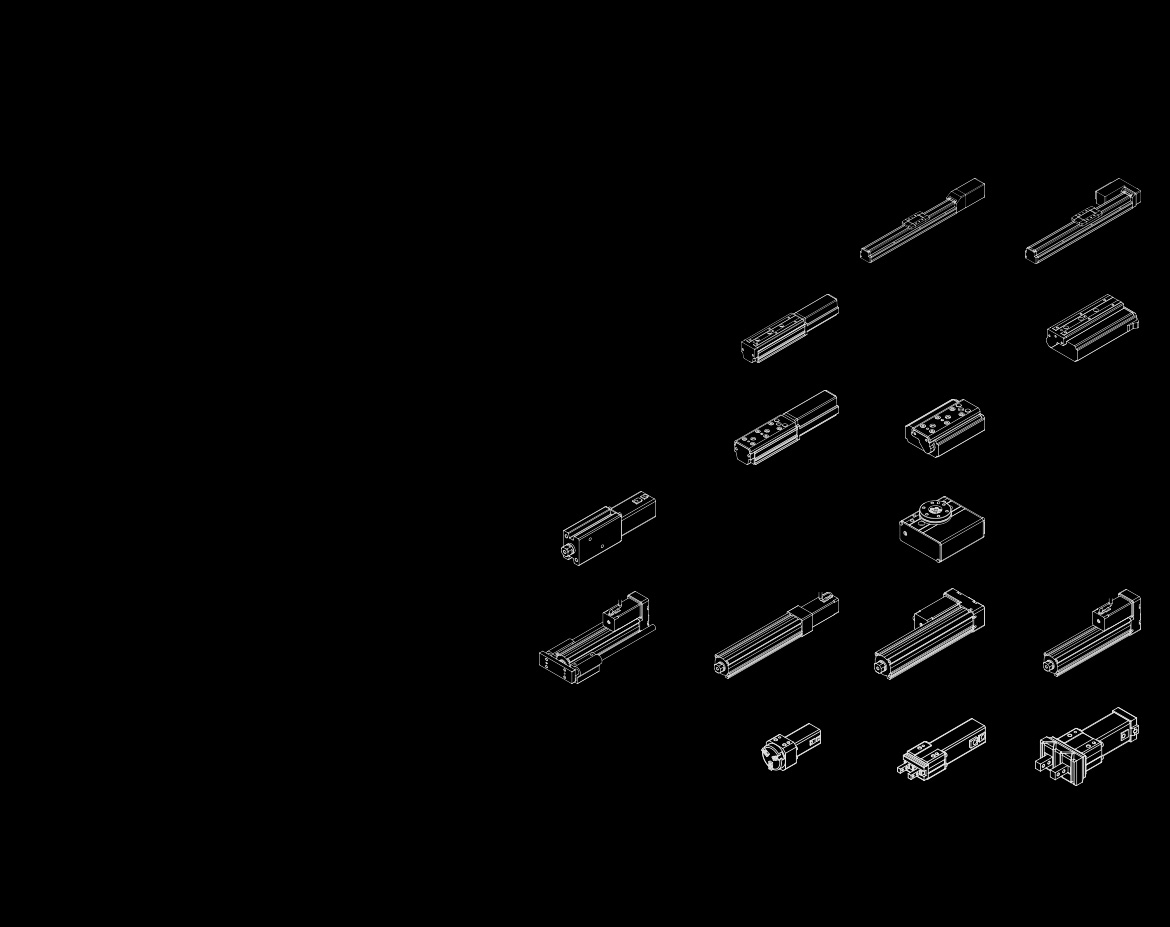

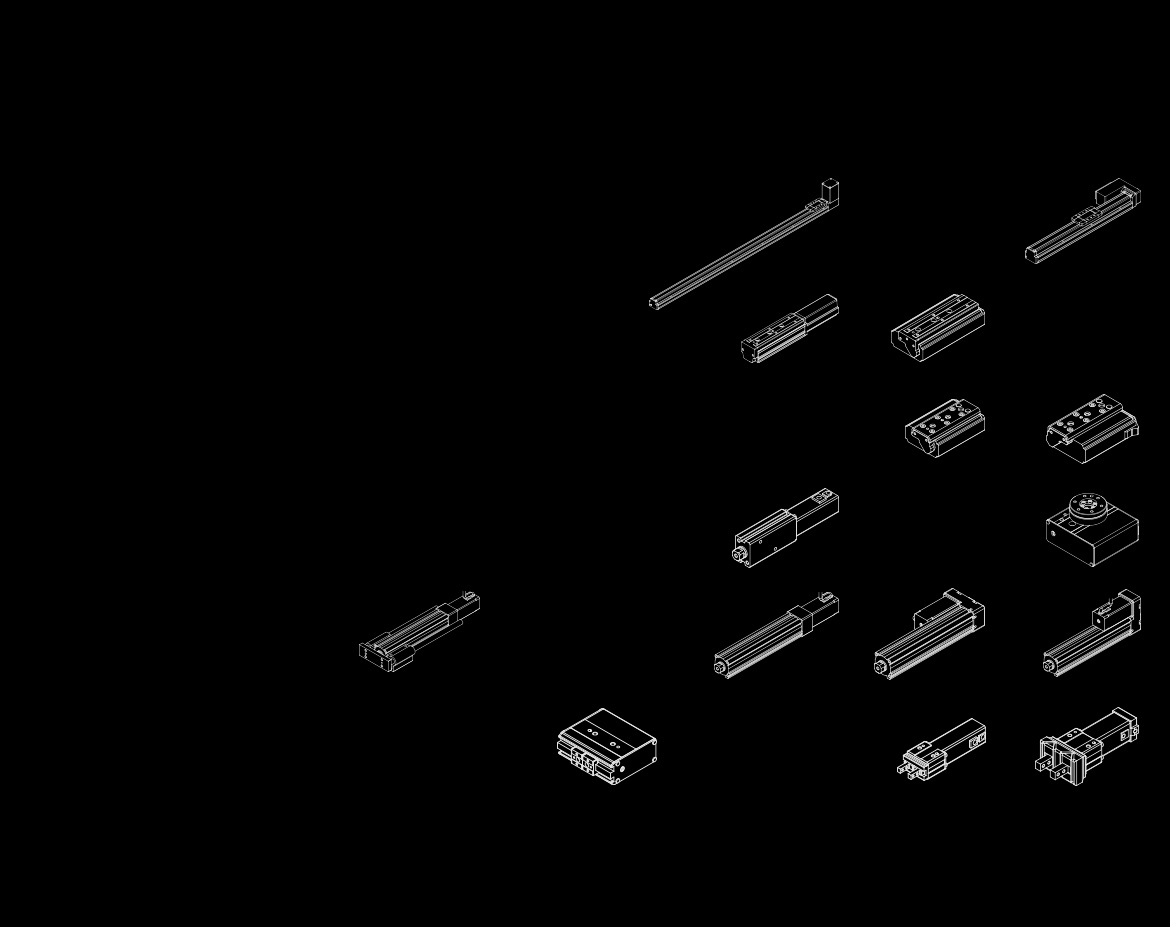

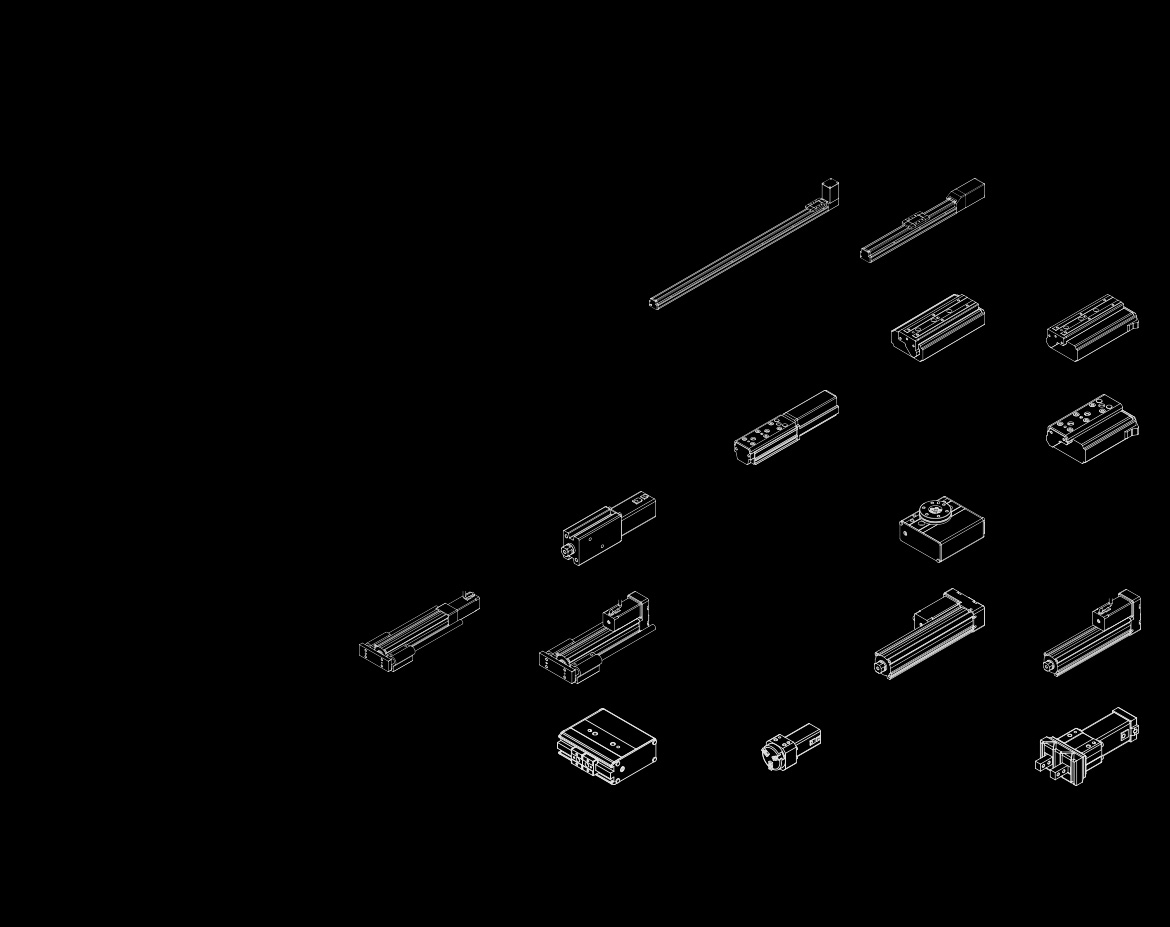

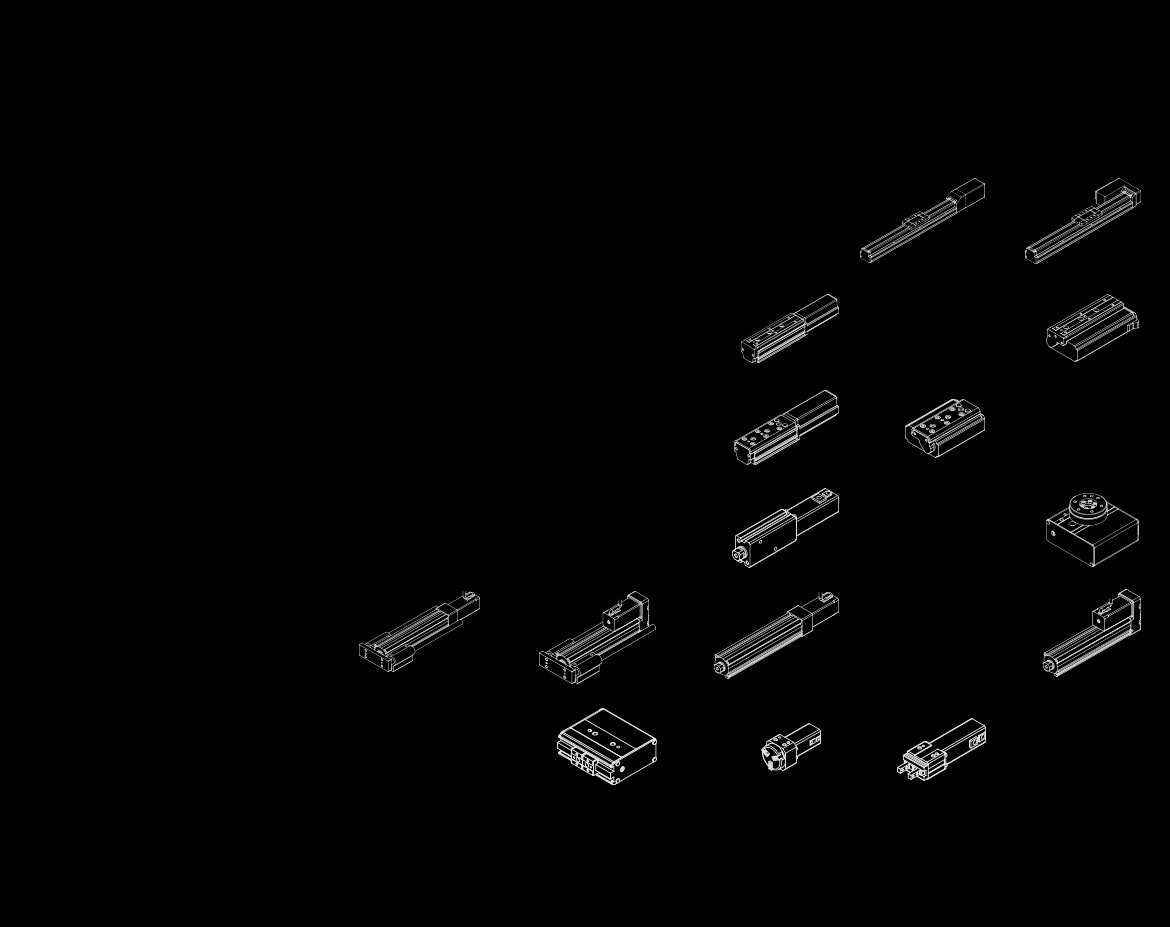

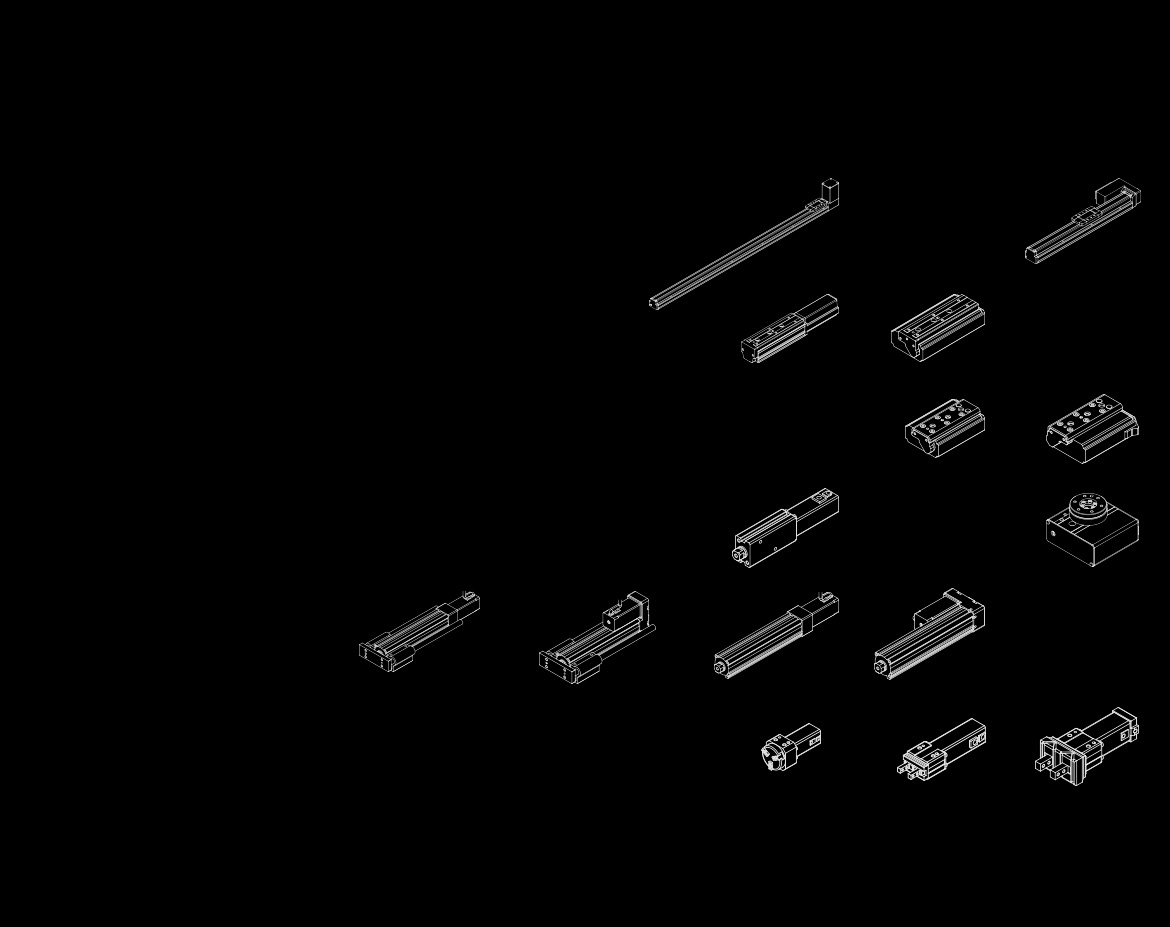

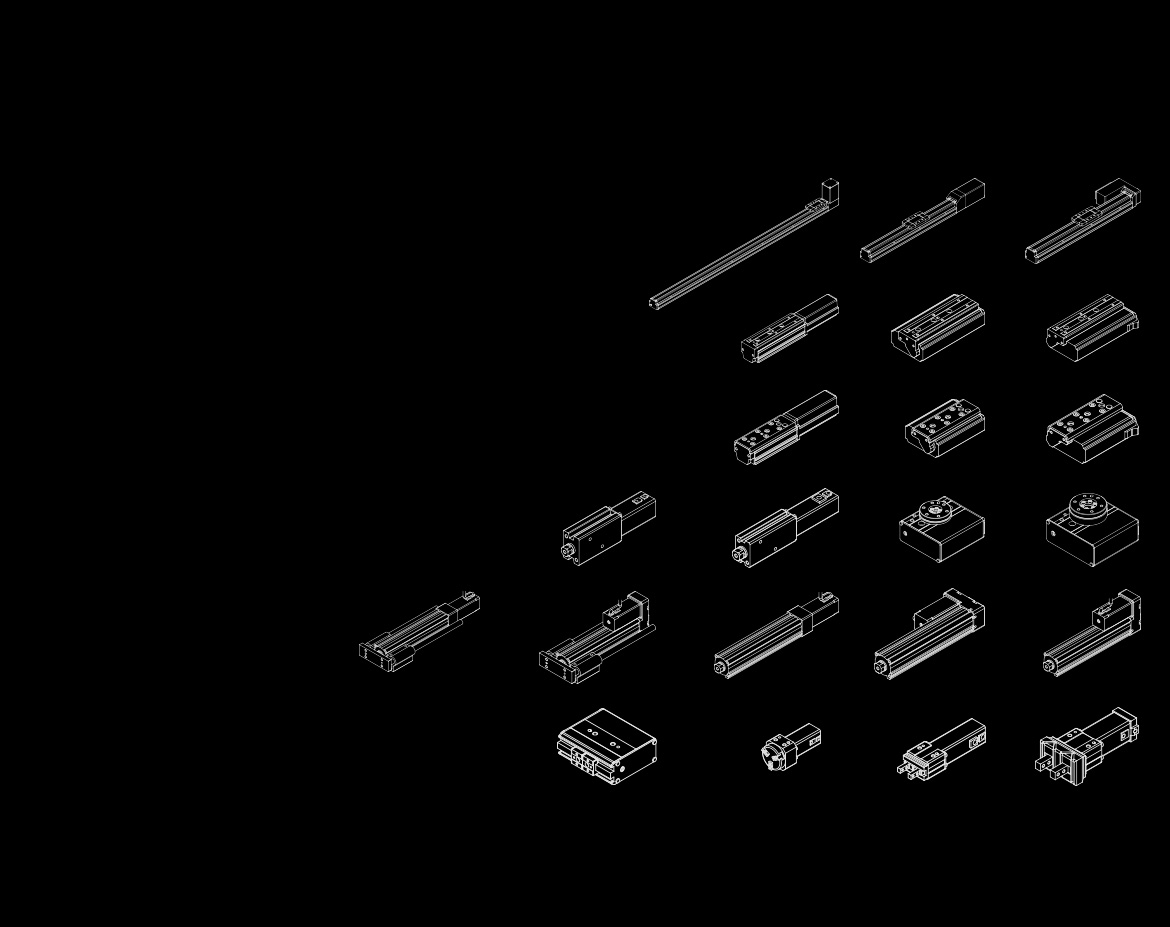

The platform offers a completely renewed lineup of all the robotic products used in a variety of automated processes including transfer,

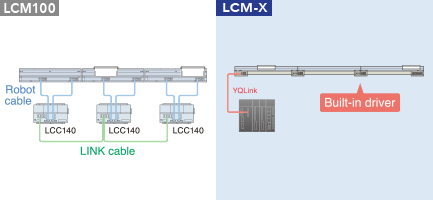

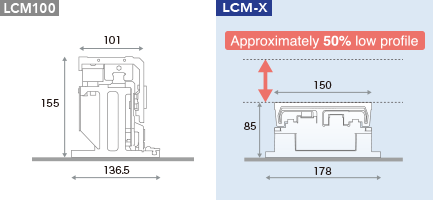

handling, assembling and image recognition, and also provides new type products such as linear conveyor module LCM-X series,

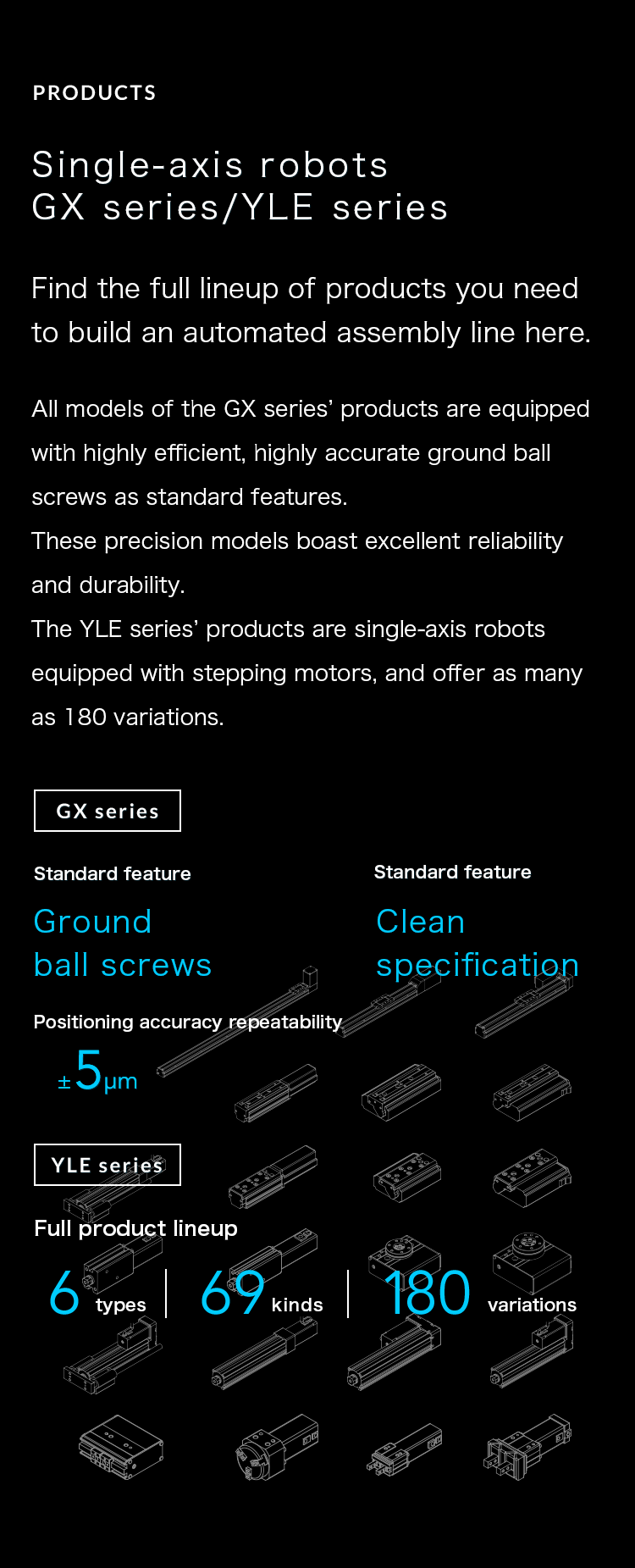

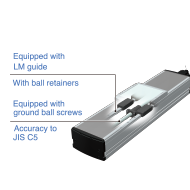

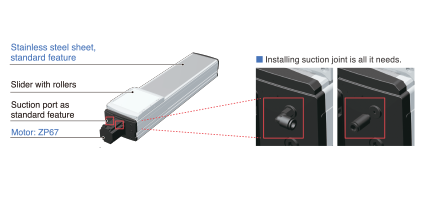

scara robot YKX series, single axis robots GX series ,YLE series and robot camera YFAEYE.

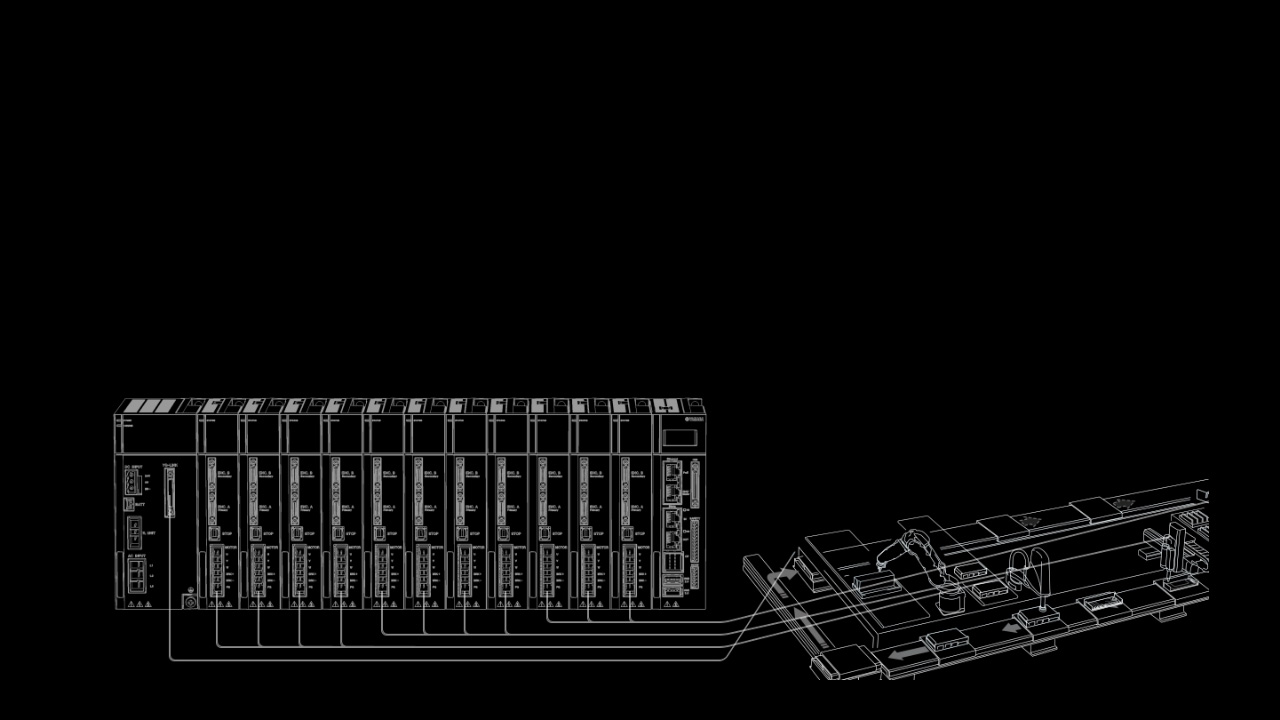

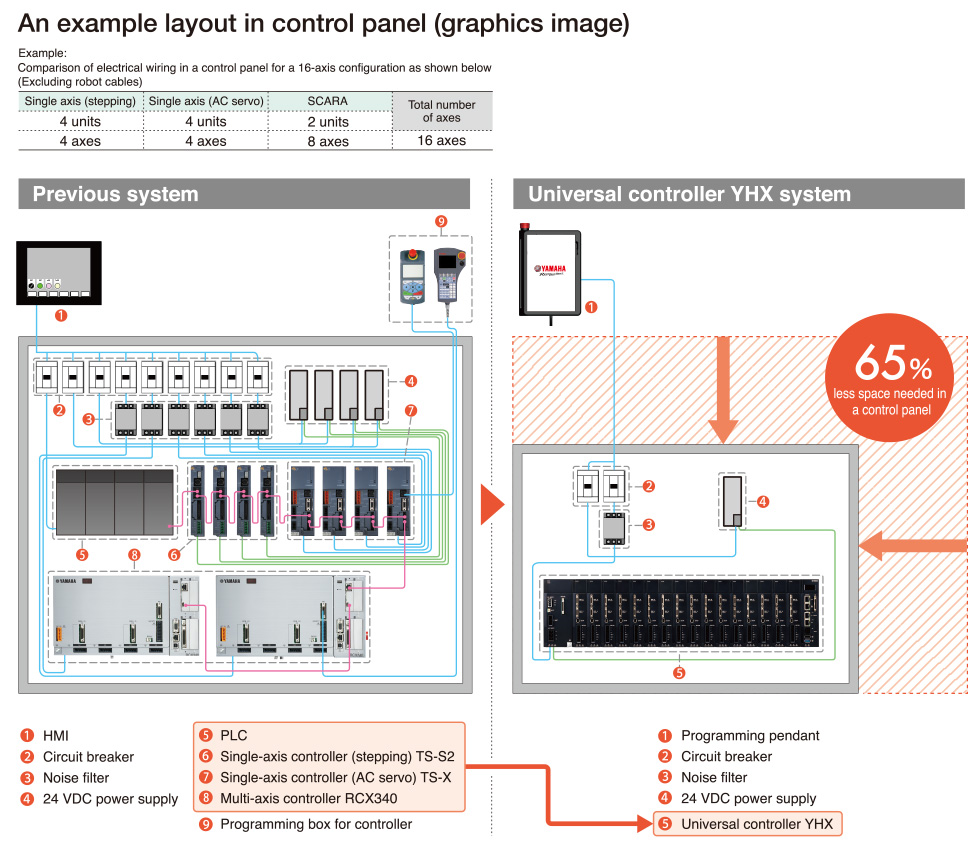

In addition to these groups of products, Yamaha is also launching the integrated type controllers YHX series,

that enables cooperative and synchronous control of these robot products.

Yamaha is confident that this product lineup will provide solutions to the challenges your factory faces,

and dramatically accelerate automated production to maximize the effects of your investment.